Add products by adding codes

Tilton Engineering 66.312 HGG 7.25″ OT-II Metallic Racing Clutches (POT Type) - Pressure Plate ONLY

Designed primarily for road racing, circle track, open wheel and formula applications, Tilton’s 7.25″ OT-II metallic racing clutches offer the low moment-of-inertia, high torque capacity and reliability necessary for the most demanding racing applications. These features have made metallic clutches the most common clutch type used in road racing and circle track racing. Metallic clutches are not recommended for street use.

Applications

- Road Racing

- Circle Track

- Open Wheel

- Formula

Tilton offers two different styles of every clutch configuration: one designed to be compatible with a step-type flywheel, and another for pot-type (“no-step”) flywheels. Step flywheels have a .100″ step for contact with the friction material of the clutch, so clutches made for this application will have a .100″ height difference between the bottom friction disc and the end of the clutch cover legs (the mounting points). Pot flywheels don’t have this step, so the friction disc and clutch cover legs will be flush on clutches designed for them.

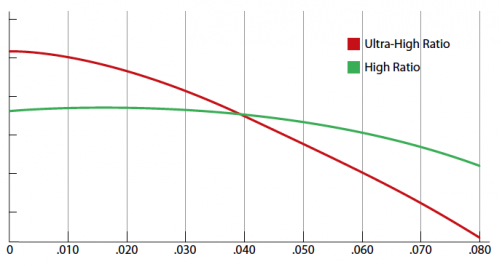

Tilton’s 7.25″ metallic clutches are available with either a High Ratio or Ultra-High Ratio pressure plate. High Ratio pressure plates offer high clamp load over a wide wear range, while Ultra-High Ratio pressure plates provide 20% more clamp load and diaphragm spring travel (modulation). As seen on the graph below, the clamp load (or torque capacity) of the High Ratio pressure plate is relatively flat until .030″ (76mm) of wear; Ultra-High Ratio pressure plates offer a higher initial clamp load at a faster wear rate.

![]()

- Standard pressure plate ratio for 7.25″ metallic clutches

- Short release travel for quick engagement and shifting

- Flat clamp load curve for longest wear range

![]()

- 20% more release travel than High Ratio for improved modulation

- 20% more clamp load than High Ratio for higher peak torque capacity

- Clamp load reduced more quickly with wear than High Ratio